Home > Bottom Loading Chamber Furnace 1700°c to 1800 °c

Bottom Loading Chamber Furnace 1700°c to 1800 °c

Overview

BEB 17/5 & 18/5 – The electrically operated elevator hearth facilitates smooth loading / unloading of the sample / crucible. The design provides a fast hearth ascent / decent therefore making it ideal for rapid load transfer application such as glass melting and firing of advanced ceramics.

| Model | Max Temp (•C) | Max Cont (•C) | Max Chamber Dims (mm) HxWxD | External Case Dims (mm) HxWxD | Chamber Capacity (litres) | Max Power (Kw) | Volts | Phase | Nett Wt. (kg) |

| BEB1715 | 1700 | 1700 | 170 x 170 x 170 | 1060 x 550 x 650 | 5 | 5.0 | 240 | 1 | 190 |

| Control Console | |||||||||

| 810 x 550 x 650 | |||||||||

| BEB1815 | 1800 | 1800 | 170 x 170 x 170 | 1060 x 550 x 650 | 5 | 6.0 | 240 | 1 | 200 |

| Control Console | |||||||||

| 810 x 550 x 650 |

BEB 17/27,91 & 227 – These models are designed for use in more industrial applications involving heavier loads and are therefore more likely to be tailored

| Model | Max Temp (oC) | Max Cont (oC) | Max Chamber Dims (mm) HxWxD | External Case Dims (mm) HxWxD | Chamber Capacity (litres) | Max Power (Kw) | Volts | Phase |

| BEB17/27 | 1700 | 1700 | 300x300x300 | 2200x800x800 | 27 | 15.0 | 400 | 3 |

| BEB17/91 | 1700 | 1700 | 450x450x450 | 2200x1000x1000 | 91 | 24.0 | 400 | 3 |

| BEB17/227 | 1700 | 1700 | 610x610x610 | 2510x1210x1210 | 227 | 36.0 | 400 | 3 |

- +91 - 40 - 6721 6354

- sales@orbitmea.com

Overview

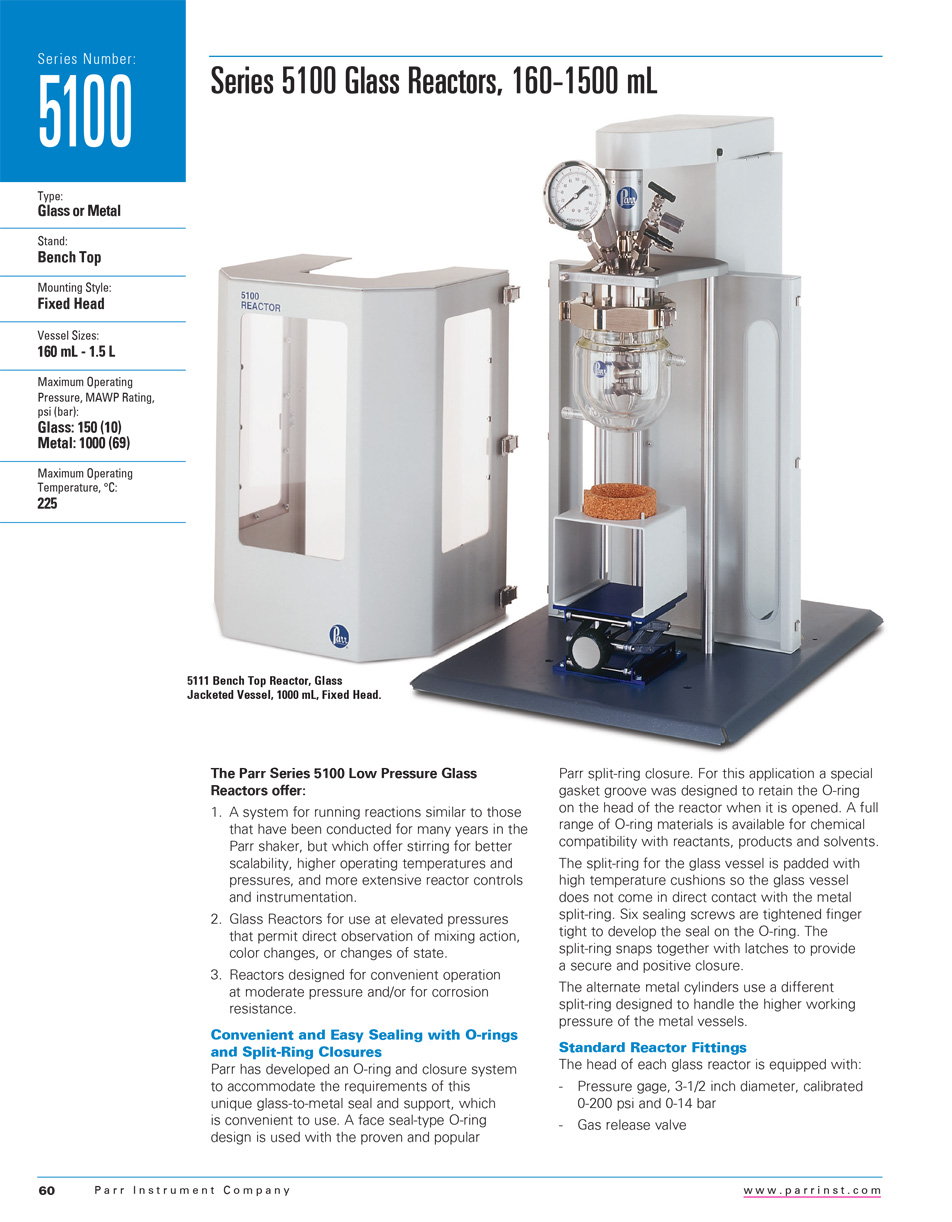

These unique reactors were developed to solve a number of problems in the lab. They allow the user to run reactions similar to those that have been conducted for many years in the Parr shaker, but offer stirring for better scalability, higher operating temperatures and pressures, and more extensive reactor controls and instrumentation. They also provide elevated pressures while also allowing direct observation of mixing action, color changes, or changes of state. These reactors also provide for convenient operation at moderate pressure and/or for corrosion resistance.

Description

Series 5100 160-1500ml Glass Reactors

These unique reactors were developed to solve a number of problems in the lab. They allow the user to run reactions similar to those that have been conducted for many years in the Parr shaker, but offer stirring for better scalability, higher operating temperatures and pressures, and more extensive reactor controls and instrumentation. They also provide elevated pressures while also allowing direct observation of mixing action, color changes, or changes of state. These reactors also provide for convenient operation at moderate pressure and/or for corrosion resistance.

- +91 - 40 - 6721 6354

- sales@orbitmea.com