Home > Split Tube Furnace – Single Zone 1100°c 1200 °c & 1700

Split Tube Furnace – Single Zone 1100°c 1200 °c & 1700

Overview

TSHH & TSVH – These furnaces are designed to meet the needs of “in –line” heating and / or when rapid cooling rates are required.

TSHH 11 & 12

- These models are heated by free radiating high grade resistance wire elements supported on ceramic tubes.

TSVH 17

- This model is heated by molybdenum disilicide elements.

| Model | Max Temp (•C) | Max Cont (•C) | Heated Length (mm) | Max Power (Kw) | Volts | Phase | Ext Dimensions (mm) Hx W x D | Nett Wt. (kg) | Worktubes (1.D x Length) nom Short Long | |

| TSHH11/90/305 | 1100 | 1050 | 305 | 2.1 | 230 | 1 | 538x405x660 | 37 | 75 x 450 | 75 x 700 |

| TSHH11/90/457 | 1100 | 1050 | 457 | 2.8 | 230 | 1 | 538x557x660 | 46 | 75 x 600 | 75 x 900 |

| TSHH11/90/610 | 1100 | 1050 | 610 | 4.2 | 230 | 1 | 538x710X660 | 72 | 75 x 750 | 75 x 1050 |

| TSHH12/90/305 | 1200 | 1150 | 305 | 2.1 | 230 | 1 | 538x405x66 | 37 | 75 x 450 | 75 x 700 |

| TSHH12/90/457 | 1200 | 1150 | 457 | 3.0 | 230 | 1 | 538x557x660 | 46 | 75 x 600 | 75 x 900 |

| TSHH12/90/610 | 1200 | 1150 | 610 | 5.0 | 230 | 1 | 538x710x660 | 72 | 75 x 750 | 75 x 1050 |

| TSHH12/90/940 | 1200 | 1150 | 940 | 6.0 | 230 | 1 | 538x1040x660 | 90 | 75 x 1050 | 75 x 1500 |

| TSVH17/90/250 | 1700 | 1650 | 250 | 4.5 | 230 | 1 | 570x650x650 | 70 | 75 x 600 | 75 x 900 |

- +91 - 40 - 6721 6354

- sales@orbitmea.com

Overview

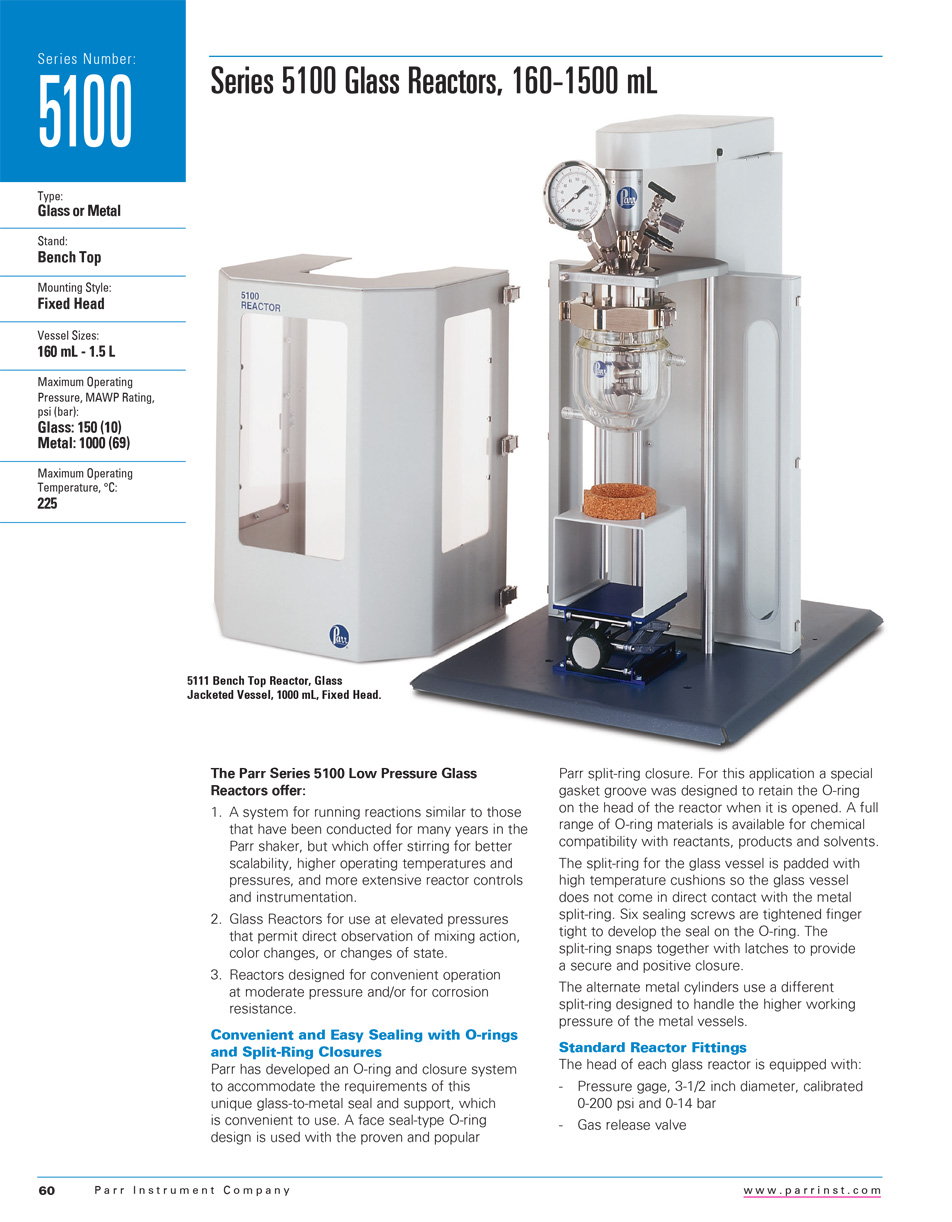

These unique reactors were developed to solve a number of problems in the lab. They allow the user to run reactions similar to those that have been conducted for many years in the Parr shaker, but offer stirring for better scalability, higher operating temperatures and pressures, and more extensive reactor controls and instrumentation. They also provide elevated pressures while also allowing direct observation of mixing action, color changes, or changes of state. These reactors also provide for convenient operation at moderate pressure and/or for corrosion resistance.

Description

Series 5100 160-1500ml Glass Reactors

These unique reactors were developed to solve a number of problems in the lab. They allow the user to run reactions similar to those that have been conducted for many years in the Parr shaker, but offer stirring for better scalability, higher operating temperatures and pressures, and more extensive reactor controls and instrumentation. They also provide elevated pressures while also allowing direct observation of mixing action, color changes, or changes of state. These reactors also provide for convenient operation at moderate pressure and/or for corrosion resistance.

- +91 - 40 - 6721 6354

- sales@orbitmea.com